Services

bodyFrom crash damage to rust repair, from dents and dings to full restoration our body works department offer a comprehensive suite of services including our temperature controlled paint booth and mixing room

|

MechanicalsApart from maintenance services, the available options are many for modern and vintage power plants. We can rebuild your car’s engine to historically correct specifications and appearance.

|

RestorationWe offer a comprehensive restoration service which includes Restoarion, Restomod and Re-Creation. To learn more about teach of these unique services please click...

|

ServiceNeed an oil change?

Radiator replacement? Engine repair? Brake pads? Clunking sounds? If you're interested in car maintenance, need an auto repair, or just have a question, don't hesitate to call us or make an appointment. |

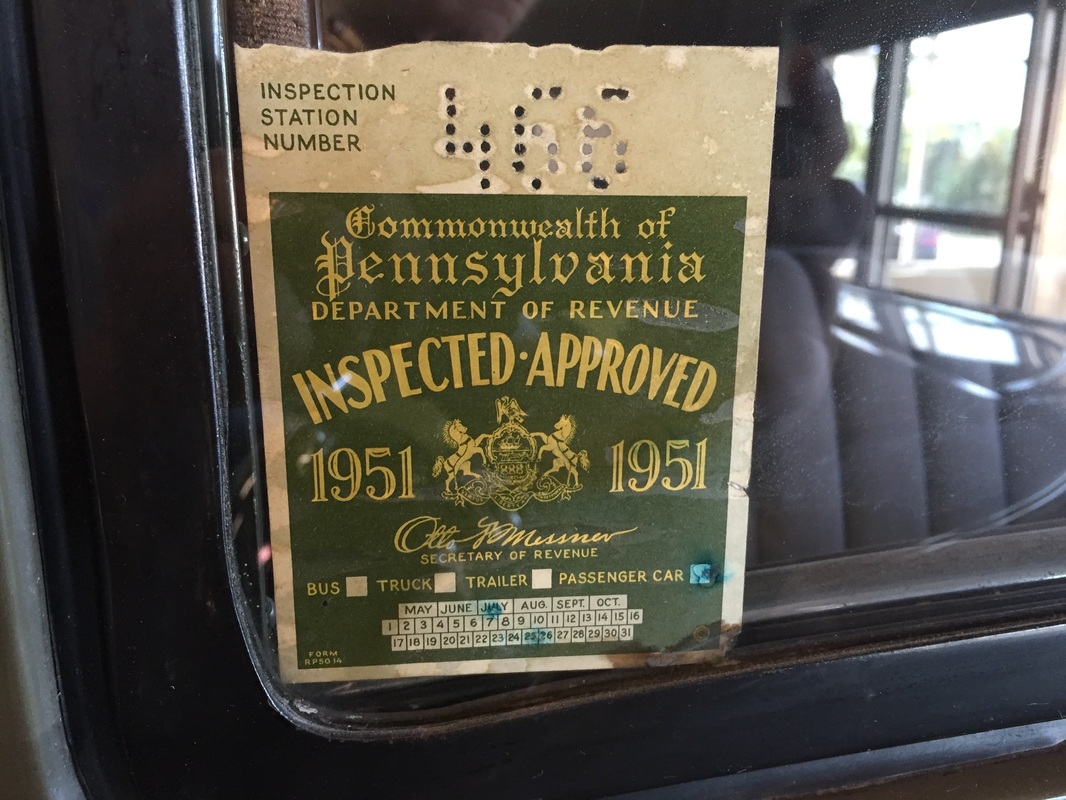

InspectionWe are an Official PennDOT Inspection Station. We perform safety inspections for passenger cars and light-duty trucks. Items checked include: suspension components, steering, braking systems, tires and wheels, lighting and electrical systems, glazing (glass), mirrors, windshield washer, defroster, wipers, fuel systems, the speedometer, the odometer, the exhaust systems, horns and warning devices, the body, and chassis.

|

otherNeed some help transporting your exotic somewhere? Wondering about winter storage locations?

Got a question about car events in the area or around the country? Need an Valuation inspection? Need an Auto Appraisal? Give us a call and we may be able to direct you to the right place! |

understanding OUR Maintenance EVALUTION PROCESS

STEP ONE: Prognostic Evaluation

Prognostics is an engineering discipline focused on predicting the time at which a system or a component will no longer perform its intended function.

This lack of performance is most often a failure beyond which the system can no longer be used to meet desired performance. The predicted time then becomes the remaining useful life (RUL), which is an important concept in decision making for repairs. Prognostics predicts the future performance of a component by assessing the extent of deviation or degradation of a system from its expected normal operating conditions.

Prognostics is an engineering discipline focused on predicting the time at which a system or a component will no longer perform its intended function.

This lack of performance is most often a failure beyond which the system can no longer be used to meet desired performance. The predicted time then becomes the remaining useful life (RUL), which is an important concept in decision making for repairs. Prognostics predicts the future performance of a component by assessing the extent of deviation or degradation of a system from its expected normal operating conditions.

OPTION ONE: Preventative Maintenance

The primary goal of maintenance is to avoid or mitigate the consequences of failure of your exotic car. This may be by preventing the failure before it actually occurs which Planned Maintenance and Condition Based Maintenance help to achieve. It is designed to preserve and restore equipment reliability by replacing worn components before they actually fail. Preventive maintenance activities include partial or complete overhauls at specified periods, oil changes, lubrication, minor adjustments, and so on. In addition, workers can record equipment deterioration so they know to replace or repair worn parts before they cause system failure. The ideal preventive maintenance program would prevent all equipment failure before it occurs.

The primary goal of maintenance is to avoid or mitigate the consequences of failure of your exotic car. This may be by preventing the failure before it actually occurs which Planned Maintenance and Condition Based Maintenance help to achieve. It is designed to preserve and restore equipment reliability by replacing worn components before they actually fail. Preventive maintenance activities include partial or complete overhauls at specified periods, oil changes, lubrication, minor adjustments, and so on. In addition, workers can record equipment deterioration so they know to replace or repair worn parts before they cause system failure. The ideal preventive maintenance program would prevent all equipment failure before it occurs.

OPTION TWO: Reliability-Centered Maintenance

Reliability-centered maintenance is a process to establish the safe minimum levels of maintenance. Sometimes you may find that their are some repairs that are going to me need to be done in the future but you just need to get through a summer driving season or an event. This type of maintenance is designed to "get you by" until we can get you car in for more in-depth preventative maintenance, rebuild or restoration.

Reliability-centered maintenance is a process to establish the safe minimum levels of maintenance. Sometimes you may find that their are some repairs that are going to me need to be done in the future but you just need to get through a summer driving season or an event. This type of maintenance is designed to "get you by" until we can get you car in for more in-depth preventative maintenance, rebuild or restoration.